When it comes to winning specifications, one factor often gets overlooked: firm standards. These internal guides, built and maintained by architecture firms, quietly shape which products get chosen.

In a recent webinar hosted by Hunley and Acelab, Vardhan Mehta, CEO and founder of Acelab, explained how firm standards work, why they matter, and how manufacturers can benefit from them.

What Are Firm Standards?

Firm standards are the internal knowledge base of an architecture firm. They capture trusted products and manufacturers, usually organized by project type or geography. In the past, these standards lived in binders or libraries. Today they might sit in spreadsheets or shared drives.

More than product lists, they reflect experience: how a manufacturer performed, whether service was reliable, and which products worked best in practice. This becomes the default playbook for architects making material decisions.

Firm Standards vs. Master Specs

Firm standards are not the same as master specifications. Master specs are template documents filled in later, often after product choices have already been made. Firm standards shape those choices much earlier. For manufacturers, that means the real win is getting into the firm standard first.

Timing and Influence

Most decisions about firm standards happen in schematic design, when architects are still open to exploring options. By later phases, changes are rare and usually tied to cost.

These decisions are often influenced by mid-level staff who document lessons from past projects and update the standards. Their feedback carries weight across the firm.

Why It Matters for Manufacturers

Being part of a firm standard creates recurring business. Once included, a manufacturer is likely to remain unless quality or service falters. The challenge is breaking in.

However, the payoff is significant. Efforts made early in the process deliver far more value than chasing late substitutions. As Vardhan noted, the long-term return from being in firm standards is enormous.

A Better Approach with SpecSuccess AI and Acelab

Maintaining standards is hard for architects because it takes time they are not paid for. As a result, many firms rely on outdated files or recycled specs. That makes it tough for manufacturers to know where to focus.

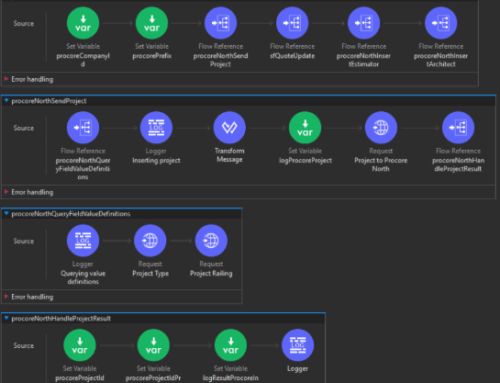

Acelab was created to close this gap. The platform helps firms manage standards and gives manufacturers a clear way to reach decision-makers. It combines product information, certifications, and research tools in one place, making it easier for firms to evaluate options early.

At Hunley, we complement this with SpecSuccess AI, which automates the follow-up work of specification sales. It captures projects, tracks submittal requests, and helps manage scheduling directly inside a CRM. Together, Acelab and SpecSuccess AI help manufacturers get in front of architects earlier and focus on building lasting relationships.

The Takeaway

For manufacturers, getting into firm standards is one of the most valuable moves you can make. It leads to repeat business, stronger retention, and greater impact from every sales effort. The key is meeting architects early with clear, accessible information.

That’s what Acelab and SpecSuccess AI were built to deliver. Find out more here.